Fire Partition Wall Board Series

Key Features of Fire Partition Wall Boards

Fireproof Insulation and Thermal Resistance

Fire partition wall boards are designed to deliver impressive fire resistance capabilities, with ratings that ensure high temperatures can be resisted without succumbing to combustion. These boards offer unmatched thermal resistance, playing a crucial role in enhancing a building's energy efficiency by maintaining a stable temperature. This minimizes the need for excessive heating or cooling, consequently reducing utility costs. For instance, many commercial buildings utilize such boards to capitalize on these benefits. Research has shown that fireproof insulation materials not only improve energy efficiency but also contribute significantly to the overall safety and sustainability of structures, particularly in high-risk environments.

Material Durability and Moisture Resistance

Fire partition wall boards are manufactured using robust materials that stand the test of time, including exposure to moisture. This durability significantly surpasses that of traditional wall materials, which require more frequent maintenance and replacement. Statistics reveal that these boards possess a considerably longer lifespan, presenting a cost-effective option for long-term use. Moisture resistance is particularly vital, as it prevents the growth of mold and other harmful deterioration processes, ensuring a healthier building environment. By incorporating fireproof boards into building designs, owners can mitigate moisture-related issues, thereby preserving the integrity and health of the structure in the long run.

ASTM E119 Compliance and Fire Ratings

The ASTM E119 standard is imperative for assessing fire resistance, depending on its significance for regulatory compliance. Fire partition wall boards are rigorously tested under this standard, achieving an array of ratings that define their resilience under fire exposure. These ratings provide a context for determining the boards' practicality and safety levels, vital for compliance with legal building codes. Numerous projects benefit from complying with ASTME119, ensuring the building's security and durability. Successful integration of fire-resistant wall boards often distinguishes projects that prioritize safety and adherence to stringent regulations, making these boards indispensable in modern construction practices.

Magnesium Oxide (MGO) Board Advantages

Magnesium Oxide (MGO) boards are increasingly recognized for their outstanding fireproof properties and environmental benefits. Known for their non-combustible nature, MGO boards undergo a unique manufacturing process where oxygen and magnesium are combined under heat and pressure, resulting in a refractory, stone-like material. This process ensures that MGO boards are chemically and physically stable at high temperatures, effectively making them ideal fireproofing solutions in construction environments. Furthermore, the use of MGO boards contributes to superior sound insulation and thermal management, surpassing many traditional materials like gypsum and plywood due to their advanced composition.

In terms of fire resistance, these boards are comparable to Class A1 fire-rated products, meaning they offer the highest level of protection against fire spread and damage. Studies and claims by manufacturers highlight how MGO boards release water vapor during fire events, which helps cool and maintain the integrity of the structure. This fire-resistant quality is supported by industry experts and has been corroborated through empirical studies, making MGO panels an effective choice for builders focused on reducing fire risks.

Comparing Fireproof Insulation Board Options

In comparing various fireproof insulation boards, it's crucial to evaluate materials like gypsum, cement board, and MGO. Each offers distinctive advantages and limitations in terms of cost-efficiency, fire ratings, and installation methods. Gypsum boards, while widely used, may not offer the same level of moisture resistance and fireproof capabilities as MGO, which is known for its durability and non-combustible properties. Cement boards are another popular choice, offering robust fire resistance but potentially lacking in flexibility compared to MGO panels.

Additionally, the installation of MGO boards can be faster than traditional methods, saving both labor and time. MGO's resistance to water and weather conditions further underscores its versatility in different climate applications. For a comprehensive understanding, businesses should assess these options considering factors like longevity, environmental impact, and upfront costs. While a tabulated comparison can offer visual clarity on metrics such as cost, fire ratings, and material composition, direct analyses show MGO leading in terms of fireproof efficacy and environmental benefits.

For further exploration of different fireproof partition board solutions, consider the available Magnesium Oxide board product options that deliver unparalleled advantages in modern construction contexts.

Top Fire Partition Wall Board Options

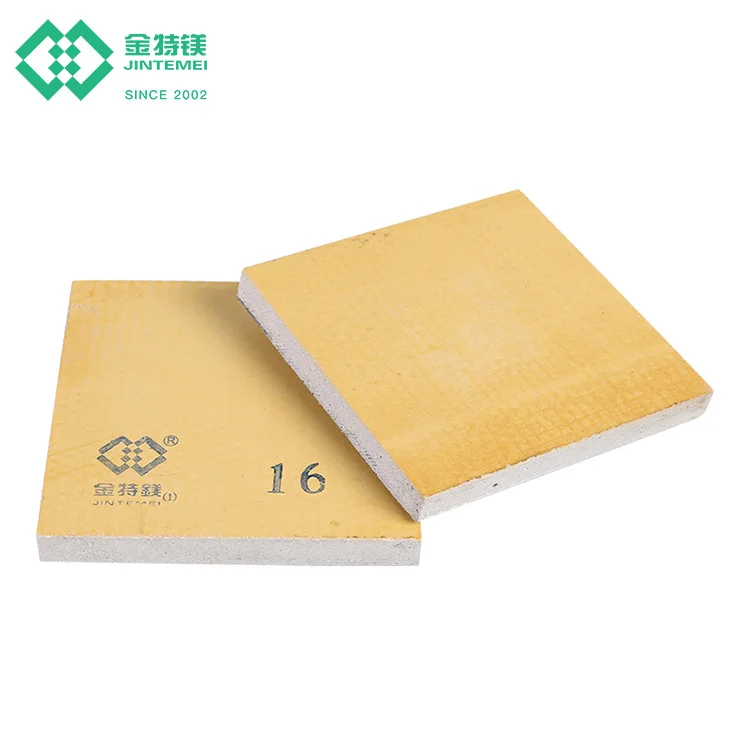

Magnesium Magnesia Board for Fireproof Steel Doors

Magnesium Magnesia boards are optimal for fireproof steel door systems, offering enhanced safety and robust constructions. These boards are known for their high impact resistance and excellent moisture management capabilities, making them suitable for high-traffic areas. The non-combustible nature of these boards significantly improves the safety of steel doors, as they do not burn, produce black smoke, or emit poisonous gases. Statistical data shows these boards can reduce insurance premiums due to their superior fire-resistant properties. For details, explore the Magnesium Magnesia Board Wall Board For Fireproof Steel Door Warehouse Farmhouse.

Chloride-Free MGO Partition Board Series

Chloride-free MGO boards present considerable advantages, particularly due to their non-corrosive properties, which make them ideal for installations in coastal regions. Without chloride, these boards ensure longevity and avoid rust, even when exposed to saline conditions common in coastal areas. Data illustrates an enhanced performance in humid and extreme weather conditions, ensuring reliability and durability. For more information, visit the 6 7 8 9 10 11 12Mm Chloride Free Wall Flooring Partition Fireproof Mgo Board.

Waterproof MGO Fireproof Wall Panel

Waterproof MGO panels are uniquely suitable for moisture-prone environments, offering exceptional fire resistance and mold prevention. Their moisture resistance is demonstrated in various projects where they have been essential, such as basement waterproofing and humid climate installations. These panels prevent mold proliferation, adding another layer of health safety to environments. Case studies highlight their essential role in successful projects where moisture and fire risk are prevalent. For product specs, see Mgo Magnesium Oxide Board Wall Board Fireproof And Waterproof Wall Panel.

Installation and Compliance Considerations

Meeting Fireproof Wall Board Standards

Ensuring the installation of fireproof wall boards meets local building codes is essential for safety and compliance. These guidelines often specify the type and rating of fireproof materials, such as the ASTM E 119 or UL 263 standards, crucial for effective installation. Compliance involves best practices like proper sealing and using the right fasteners to maintain the structural integrity of fireproof wall boards. To aid adherence to these codes, resources from regulatory bodies like the National Fire Protection Association (NFPA) and local building authorities provide guidance and support.

Maintenance for Long-Term Fire Resistance

Maintaining fire partition wall boards is vital for their longevity and effectiveness. Regular maintenance routines should include cleaning, inspecting for damage, and ensuring that the sealant and fasteners are intact to prevent deterioration. Routine inspections can help identify any issues early, thus preventing potential hazards. According to fire safety organizations, ongoing maintenance is crucial to ensuring that fire resistance performance remains optimal over time, safeguarding both property and occupants. Regularly updated maintenance protocols can significantly enhance the safety profile of buildings equipped with such panels.

EN

EN